sales@fvfindia.com View Mobile Number

Service Valves

Leading Manufacturers, Exporters and Wholesaler of Ammonia Service Valves, Chlorine Dioxide Service Valves, Chlorine Service Valves, Cryogenic Service Valves, High Temperature Service Valves, Hydrogen Service Valves, Lithium Service Valves, Low Temperature Service Valves, Oxygen Service Valves, Phosphoric Acid Service Valves, Seawater Service Valves, Sulphuric Acid Service Valves and Vinyl Chloride Monomer(Vcm) Service Valves from Mumbai.

| Business Type | Manufacturer, Exporter, Supplier |

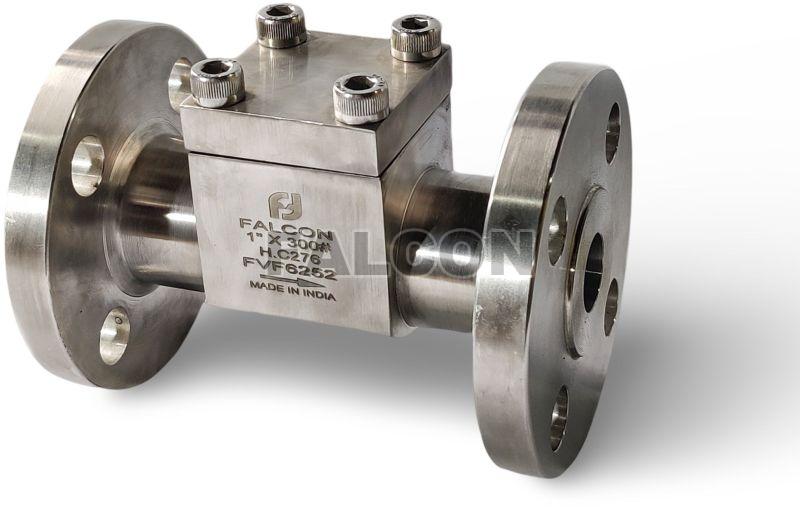

| Brand Name | FALCON |

| Material | Stainless Steel |

| Finishing | Polished |

| Condition | New |

| Automatic Grade | Manual |

| Usage | Ammonia |

| Certification | ISO 9001:2008 Certified |

| Product Code | FVFAM1 |

| Port | JNPT |

| Payment Terms | L/C, D/P, T/T |

| Delivery Time | 6 WEEK |

| Packaging Details | EXPORT WOODEN PACKING |

Falcon Valves and Flanges Pvt Ltd. offers a specialized range of Ammonia Service Valves, meticulously engineered to ensure safe and reliable operation in challenging ammonia applications. Recognizing the highly corrosive, toxic, and flammable nature of ammonia, our valves are designed with critical considerations for material selection, sealing integrity, and rigorous cleaning procedures.

Manufactured from carefully chosen material grades such as carbon steel for anhydrous ammonia and stainless steel for applications where moisture may be present, our ammonia valves minimize the risk of corrosion and stress cracking. Each valve undergoes stringent cleaning and testing protocols to eliminate any traces of oil, grease, or hydrocarbons, crucial for preventing hazardous reactions with ammonia. With various pressure ratings and valve types available, Falcon Ammonia Service Valves provide a robust and secure solution for critical flow control in industries like fertilizers, refrigeration, and chemical processing.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | FALCON |

| Product Code | FVFCLO2 |

| Port | JNPT |

| Payment Terms | L/C, D/A, D/P, T/T |

| Delivery Time | 6 WEEK |

| Packaging Details | EXPORT WOODEN BOX |

Because Chlorine Dioxide is highly unstable and aggressive (often more corrosive than wet chlorine), Falcon utilizes specialized exotic alloys and severe-service designs to ensure safety and longevity.

1. Material GradesFor Chlorine Dioxide service, standard stainless steels (like 304/316) typically fail due to stress corrosion cracking. Falcon offers valves in high-grade exotic alloys specifically resistant to oxidizing environments:

-

Primary Grades:Hastelloy C-276 (UNS N10276) and Titanium Grade 2 (Commercially Pure) or Grade 5.

-

Alternative High-Performance Alloys: Hastelloy C-22, Super Duplex (UNS S32750/S32760), and PVDF-Lined or PFA-Lined carbon steel (for lower temperature/pressure applications).

-

Trims: Often matched to the body material (e.g., Titanium trim in a Titanium body) to prevent galvanic corrosion.

Falcon offers a wide range of sizes to accommodate different piping scales, from dosing lines to main process headers:

-

Standard Range:1/2" (DN15) to 24" (DN600).

-

Specialty/Large Bore: Up to 48" (DN1200) for specific butterfly or gate valve configurations upon request.

-

Pressure Ratings: Typically Class 150# to Class 900# (PN20 to PN150), with higher pressure classes available for specific injection systems.

Falcon provides several valve architectures optimized for hazardous chemical handling:

-

Ball Valves: The most common choice for ClO₂. Available in Floating and Trunnion Mounted designs. They feature Full Bore flow to minimize pressure drop and cavity-free (or cavity-filled) seats to prevent ClO₂ gas accumulation inside the valve body.

-

Plug Valves: Sleeved plug valves (often PTFE/PFA sleeved) offer a cavity-free design that is excellent for preventing the entrapment of unstable ClO₂.

-

Butterfly Valves: High-Performance Triple Offset valves for larger diameter lines. These provide bubble-tight shutoff using metal-to-metal or laminated seals compatible with corrosive gases.

-

Check Valves: Swing or Dual Plate check valves (with Hastelloy springs/internals) to prevent backflow into generation systems.

-

Globe Valves: For precise flow throttling of precursor chemicals or ClO₂ solution.

Falcon employs rigorous standards to handle the toxicity and explosiveness of Chlorine Dioxide:

-

Design Standards: Designed in accordance with ASME B16.34, API 6D, and API 600.

-

Sealing Technology: Features Low Fugitive Emission packing (certified to ISO 15848-1 or API 622) to prevent toxic gas leakage into the atmosphere.

-

Cleaning: Valves undergo "Oxygen Cleaning" or specialized Chlorine Cleaning processes to remove all oil, grease, and hydrocarbons which can react explosively with Chlorine Dioxide.

-

Testing: Rigorous testing includes Hydrostatic Body Testing (1.5x design pressure), High-Pressure Pneumatic Seat Testing, and Helium Leak Testing to ensure zero leakage.

-

Manufacturing: Investment casting (lost wax) for smaller sizes to ensure high surface finish and defect-free casting; Forged bodies for high-pressure small-bore valves to ensure structural integrity.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | FALCON |

| Base Material | ASTM A494 CW12MW , ASTM B381 TITANIUM GRADE 2 AND ASTM B381 TITANIUM GRADE 5 |

| Application | CHLORINE SERVICE |

| Grade | HASTELLOY C276 AND TITANIUM GRADE 2 |

| Product Code | FVFCHLR1 |

| Port | JNPT |

| Payment Terms | L/C, D/P, T/T |

| Delivery Time | 6 WEEK |

| Packaging Details | EXPORT WOODEN PACKING |

Falcon Valves and Flanges Pvt Ltd. proudly presents its highly specialized Chlorine Service Valves, expertly engineered for the extreme demands of chlorine applications. Given the highly corrosive nature of both wet and dry chlorine, our valves are meticulously crafted from premium Hastelloy and Titanium grades, offering unparalleled resistance to pitting, crevice corrosion, and stress corrosion cracking.

With a proven track record, Falcon Chlorine Service Valves have been successfully deployed in numerous critical projects for industry leaders such as SABIC Saudi Arabia and Transco Abu Dhabi, demonstrating our commitment to delivering reliable, long-lasting solutions for the safe handling of chlorine in chemical processing, water treatment, and other vital sectors.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Cryogenic Gate Valves, Cryogenic Globe Valves, Cryogenic Ball Valves, Cryogenic Butterfly Valves |

| Valve Size | 1/2" TO 24" |

| Material | Grade 304/304L (Cast: CF8/CF3), Grade 316/316L (Cast: CF8M/CF3M), ASTM A350 LF2,ASTM A352 LCB/LCC |

| Number Of Way | 2way |

| Brand Name | FALCON |

| Connection Type | Flanged |

| Pressure Rating | ANSI CLASS 150 -2500 |

| Temperature Rating | -40°C TO -269°C |

| Product Code | FVFCSV1 |

| Port | JNPT |

| Payment Terms | L/C, D/P, T/T |

| Delivery Time | 6 WEEK |

| Packaging Details | EXPORT WOODEN BOX |

At Falcon, we provide specialized cryogenic valve solutions engineered to perform in the most demanding ultra-low temperature environments. From the massive scale of LNG (Liquefied Natural Gas) terminals to precision industrial gas applications, our valves ensure safety, zero-leakage, and operational integrity where standard equipment fails.

Core SpecializationsOur cryogenic range is designed for media that must be kept in a liquid state through extreme refrigeration, including LNG (-162°C), Liquid Nitrogen (-196°C), Liquid Oxygen, and Liquid Hydrogen.

-

Extended Bonnet Design: All Falcon cryogenic valves feature an extended bonnet (per BS 6364) to keep the stem packing at ambient temperature, preventing freeze-up and ensuring smooth actuation.

-

Cavity Pressure Relief: To prevent catastrophic failure from liquid expansion (boil-off) trapped in the valve cavity, our designs incorporate automatic internal pressure relief systems.

-

Low-Temperature Metallurgy: We utilize high-grade austenitic stainless steels (304L, 316L) and specialized alloys that maintain high impact strength and ductility at temperatures as low as -196°C.

| Industry | Applications | Media Handled |

| LNG Value Chain | Liquefaction, Storage, Marine Transport & Regasification | Methane (LNG) |

| Air Separation | Industrial gas production units (ASU) | Oxygen, Nitrogen, Argon |

| Aerospace | Rocket engine testing and fueling systems | Liquid Hydrogen & Oxygen |

| Healthcare | Medical gas storage and cryo-preservation | Liquid Oxygen, Helium |

-

Design Standards: API 6D, ASME B16.34, BS 6364, and ISO 28921.

-

Testing: Every valve undergoes rigorous Helium Leak Testing and cryogenic submersion tests at -196°C to guarantee bubble-tight performance.

-

Sealing Technology: Features PCTFE or TFM soft inserts for bubble-tight shut-off, or specialized metal-to-metal seating for severe service.

-

Safety: Inherently Fire Safe designs certified to API 607/ISO 10497.

Note: Our valves are available in manual, pneumatic, or electric configurations, with actuators specifically lubricated for low-temperature reliability.

Our Cryogenic Product RangeEvery Falcon cryogenic valve features an extended bonnet design. This critical feature creates a "gas column" that keeps the stem packing away from the cryogenic fluid, preventing freeze-ups and ensuring bubble-tight sealing at the gland.

-

Cryogenic Gate Valves: Ideal for full-flow, low-pressure drop isolation in LNG storage and transport.

-

Cryogenic Globe Valves: Precision-engineered for throttling and regulating flow in cryogenic pipelines.

-

Cryogenic Ball Valves: High-performance, quarter-turn valves for rapid shut-off, featuring pressure-relieving seats to prevent over-pressure due to liquid expansion.

-

Cryogenic Check Valves: Robust designs to prevent backflow in liquid gas systems, ensuring plant safety.

-

Cryogenic Butterfly Valves: Compact, lightweight solutions for large-diameter cryogenic service, often utilized in marine and processing terminals.

For cryogenic service, Austenitic Stainless Steels are the industry standard because they remain ductile and resist brittle fracture at temperatures as low as -196°C. The most common grades are SS 304/304L (CF8/CF3) for general liquid nitrogen and oxygen service, and SS 316/316L (CF8M/CF3M), which is preferred for LNG and marine environments due to its superior corrosion resistance. For high-pressure or high-cycle components, nitrogen-strengthened grades like Nitronic 50 are utilized to ensure mechanical integrity under extreme thermal stress.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Metal seated Ball valves, Triple offset butterfly valves, Gate valves, globe valves, check valves |

| Valve Size | 1/2" to 48" |

| Material | A217 WC6, A217 WC9, A217 C12A, ASTM A351 CF8C, ASTM A351 CK20, Inconel 625, Inconel 718 |

| Number Of Way | 2way |

| Brand Name | FALCON |

| Connection Type | Flanged |

| Pressure Rating | ANSI CLASS 150 -2500 |

| Temperature Rating | +260°C TO +1000°C |

| Product Code | FVFHTSV1 |

| Port | JNPT |

| Payment Terms | L/C, D/A, D/P, T/T |

| Delivery Time | 6 WEEK |

| Packaging Details | EXPORT WOODEN BOX |

Falcon Manufacturing specializes in the precision engineering and production of high-temperature valves designed for the most demanding industrial environments. By integrating advanced metallurgy with specialized machining techniques, Falcon ensures peak performance where standard components fail.

Core Competencies & Technical MasteryFalcon’s reputation is built on its ability to handle "unworkable" materials and achieve microscopic tolerances:

-

Stellite™ Specialists: Expertise in applying and machining cobalt-based Stellite alloys. This provides exceptional resistance to wear, galling, and corrosion at extreme temperatures.

-

Precision Machining: Utilizing specialized heavy-duty machinery tailored for high-nickel alloys and hardened steels.

-

Lapping & Grinding: Advanced finishing processes that ensure bubble-tight seals and metal-to-metal seating, critical for high-pressure safety.

-

Custom Engineering: In-house design capabilities to modify valve geometry for specific thermal expansion requirements.

Falcon produces a wide range of valve types, each optimized for high-heat cycles:

| Valve Type | Primary Application | Key Feature |

| Gate Valves | Isolation in steam/oil lines | Low pressure drop; Stellite-faced seats. |

| Globe Valves | Throttling and flow regulation | High durability under frequent cycling. |

| Check Valves | Backflow prevention | Rapid response with heat-resistant springs. |

| Ball Valves | Quick shut-off (Severe Service) | Metal-seated designs for abrasive media. |

| Control Valves | Automated process modulation | Precision-ground stems for smooth actuation. |

Falcon Manufacturing & Design provides high-integrity sealing solutions across all major industry standards, specifically focusing on metal-seated valves that survive extreme thermal cycling.

Leakage Class CapabilitiesFalcon manufactures valves according to ANSI/FCI 70-2 and API 598 standards. Their specialized lapping and grinding processes allow them to achieve superior shut-off even in metal-to-metal configurations:

-

Class IV (Standard Industrial): The benchmark for metal-seated valves, allowing a maximum of 0.01% leakage of rated capacity. Ideal for general steam and hydrocarbon service.

-

Class V (Critical/High-Pressure): A rigorous standard for high-pressure applications where leakage must be minimal (measured in microliters per inch of orifice). Falcon achieves this through precision Stellite™ seat grinding.

-

Class VI (Bubble-Tight): While typically reserved for soft-seated valves, Falcon’s Triple Offset Butterfly Valves and high-precision metal-seated ball valves are engineered to achieve bubble-tight, zero-leakage performance in critical gas and hazardous liquid services.

Falcon works with an extensive range of materials to ensure chemical compatibility and structural integrity at temperatures ranging from -268°C to 540°C (-450°F to 1000°F).

| Material Category | Specific Grades Offered |

| Hard-Facing (Trim) | Stellite 6, Stellite 12, Stellite 21 (for superior wear/erosion resistance). |

| Stainless Steel | SS304/L, SS316/L, SS904L, 254 SMO. |

| Carbon & Alloy Steel | WCB, WCC, LCB, LCC, WC6, WC9, C5, C12. |

| High-Nickel Alloys | Inconel (600, 625), Hastelloy (B, C276), Monel 400. |

| Advanced Steels | Duplex and Super Duplex Stainless Steel. |

| Specialty | Nickel Aluminum Bronze, Titanium, and Alloy 20. |

-

Sealing Technology: Seats are available in Integral, Renewable, or Weld-deposited (Stellite) formats.

-

Testing Rigor: Every valve undergoes hydrostatic and pneumatic testing per BS 5146 or API 598 to verify the specified leakage class before dispatch.

-

Precision Finishing: Their in-house lapping and grinding machines are specifically designed to handle hard-faced surfaces, ensuring a mirror finish that prevents "wire-drawing" and premature seat failure in high-velocity steam.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | FALCON |

| Material | Stainless Steel |

| Finishing | Polished |

| Condition | New |

| Automatic Grade | Manual |

| Pressure | Upto 15000 psi |

| Usage | Hydrogen service |

| Size | 1/4" to 4" |

| Product Code | FVFHY1 |

| Port | JNPT |

| Payment Terms | L/C, D/P, T/T |

| Delivery Time | 6 WEEK |

| Packaging Details | EXPORT WOODEN PACKING |

As the world transitions towards a cleaner energy future, hydrogen is emerging as a pivotal fuel source. At Falcon Valves and Flanges Pvt Ltd., we are proud to be at the forefront of this revolution, offering a comprehensive range of Hydrogen Service Valves designed and manufactured to meet the stringent demands of the entire hydrogen value chain – from generation to fueling stations.

Engineered for Excellence: The Falcon Advantage in Hydrogen Service

Handling hydrogen presents unique challenges due to its small molecular size, high diffusivity, and potential for hydrogen embrittlement in certain materials. Falcon 's Hydrogen Service Valves are meticulously engineered to overcome these challenges, ensuring unparalleled safety, leak-tightness, and long-term reliability.

Key Features and Benefits:

- Forged Construction for Unmatched Integrity: Unlike cast valves, our hydrogen valves are primarily manufactured through the forging process. This ensures a superior grain structure, eliminating internal defects, voids, and porosity that can compromise integrity under high pressures and the unique demands of hydrogen. Forging provides exceptional strength, ductility, and resistance to hydrogen-induced degradation.

- Optimized Material Selection: SS316Ti and Beyond: We utilize premium material grades, with SS316Ti (Stainless Steel 316Ti) being a cornerstone of our hydrogen valve range. SS316Ti is a titanium-stabilized austenitic stainless steel known for its enhanced resistance to intergranular corrosion, particularly at elevated temperatures, and its improved mechanical properties. This makes it an ideal choice for challenging hydrogen environments where material stability is paramount. For specific applications requiring even greater resistance to hydrogen embrittlement or extreme conditions, we offer valves in other specialized material grades on request.

- Leakage Prevention: A Critical Imperative: Hydrogen 's small molecular size makes leak prevention crucial for both safety and efficiency. Our valves incorporate advanced sealing technologies, precision machining, and rigorous testing protocols to ensure zero fugitive emissions. This includes specialized packing designs and tight tolerances, critical for preventing hydrogen escape throughout the system.

- Comprehensive Application Coverage: Falcon Hydrogen Service Valves are designed to perform across the entire hydrogen ecosystem, including:

- Hydrogen Production: Valves for electrolysis, steam methane reforming, and other generation processes, handling various pressures and temperatures.

- Hydrogen Compression and Storage: Robust valves built to withstand high pressures for efficient compression and safe storage in tanks and cylinders.

- Hydrogen Transportation: Reliable solutions for pipeline and mobile transport applications.

- Hydrogen Fueling Stations: Precision control valves for safe and efficient dispensing of hydrogen to vehicles.

- Rigorous Quality Assurance: Every Falcon Hydrogen Service Valve undergoes stringent quality control procedures and comprehensive testing, including helium leak testing, to verify absolute integrity and performance under the most demanding conditions.

Choose Falcon Hydrogen Service Valves for a secure, efficient, and sustainable future, where the power of hydrogen flows reliably and safely.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | KNIFE GATE VALVE, BUTTERFLY VALVES, SHUT OFF VALVES, CHECK VALVES |

| Valve Size | 1/2" TO 24" |

| Material | Titanium Grade 2 and 5, Hastelloy® C276, Monel® 400, Inconel® 625, Duplex 2205, Super Duplex 2507, |

| Number Of Way | 2way |

| Brand Name | FALCON |

| Connection Type | Flanged, BUTTWELD, SOCKET WELD, THREADED |

| Pressure Rating | ANSI CLASS 150 -2500 |

| Temperature Rating | -60 C TO + 450 C |

| Product Code | FVFLSV1 |

| Port | JNPT |

| Payment Terms | L/C, D/A, D/P, T/T |

| Delivery Time | 6 WEEK |

| Packaging Details | EXPORT WOODEN BOX |

Falcon Valves and Flanges Pvt. Ltd. manufactures a specialized line of service valves designed specifically for high-consequence chemical environments, including Lithium service (often associated with Lithium Hydroxide or Lithium Brine processing).

Because lithium compounds—particularly in liquid or slurry form—can be highly abrasive, corrosive, and prone to crystallization, these valves are engineered for extreme durability and sealing integrity.

Core Design Features

Specialized Material Selection: To resist the chemical degradation caused by lithium salts and alkalis, Falcon utilizes high-grade materials such as Titanium Grade 2, Alloy 20, Hastelloy, Duplex/Super Duplex Stainless Steel, and Monel.

Leak-Proof Sealing: Designed to prevent the escape of hazardous lithium-based fluids, these valves often feature enhanced gland packing and reinforced seat designs to maintain a tight shut-off.

Anti-Crystallization Design: Many of these valves are designed with smooth internal flow paths to prevent "dead zones" where lithium salts might settle and crystallize, which could otherwise lead to valve jamming or seat damage.

Standard Compliance: They are typically manufactured to meet international standards such as API 600, API 6D, API 607 (Fire Safe), and ISO 15848 (Fugitive Emissions).

Technical Specifications

| Feature | Common Range / Capability |

| Valve Types | Ball, Gate, Globe, Check, and Butterfly |

| Pressure Ratings | 150# to 2500# |

| Temperature Range | Designed for cryogenic to high-temperature chemical processes |

| Operation | Manual (Handwheel/Gear) or Automated (Pneumatic/Electric Actuators) |

| End Connections | Flanged (ANSI/DIN), Butt-weld, or Socket-weld |

Key Applications

Lithium Mining & Extraction: Handling aggressive brines and acidic solutions during the leaching process.

Battery Chemical Processing: Specifically for the production of Lithium Hydroxide and Lithium Carbonate.

Refining: Used in the chemical treatment and purification stages where moisture-sensitive or corrosive lithium compounds are present.

Falcon Valves and Flanges Pvt. Ltd. provides specialized flow-control solutions for the lithium industry, focusing on the unique challenges of brine extraction and chemical refinement. Lithium service is particularly demanding because the media—often high-concentration brines or chemical slurries—is both highly corrosive and highly abrasive, with a tendency to crystallize and seize moving parts.

Below are the expanded technical and design details for these valves:

1. Advanced Material Engineering

Standard stainless steel often fails in lithium brine service due to chloride-induced pitting. Falcon utilizes superior alloys to ensure longevity:

Body & Gate/Ball: High-grade alloys like Hastelloy C276, Titanium (Grade 2 or 5), Super Duplex (SS 2507), and Alloy 20.

Linings: For acidic slurries or leaching processes, valves may feature PFA/FEP linings or full body liners that protect the metal from direct contact with aggressive media.

2. Anti-Crystallization & Slurry Design

Lithium salts (Lithium Carbonate/Hydroxide) readily precipitate out of solution, which can "freeze" a valve.

Self-Cleaning Seats: In ball valves, the seat design often includes a "scraping" action to clear crystals from the ball surface during every cycle.

Knife Gate Technology: For lithium slurries, Falcon provides Knife Gate Valves that can cut through thick media and solids. These often feature a "bottomless" or "through-conduit" design so that solids are pushed out rather than trapped in the seat pocket.

Cavity Fillers: Ball valves can be fitted with PTFE cavity fillers to eliminate dead spaces where brine could settle and crystallize.

5. Critical Process Applications

Evaporation Pond Management: Handling raw, concentrated brine.

- Ion Exchange & Solvent Extraction: Control of purified lithium streams.

- Precipitation Tanks: Regulating the flow of sodium carbonate/lime mixtures during the chemical conversion of lithium.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Ball, Gate, Globe, Check, Butterfly, Safety valve, Control valves, Plug valves |

| Valve Size | 1/2" TO 24" |

| Material | Grade 304/304L (Cast: CF8/CF3), Grade 316/316L (Cast: CF8M/CF3M), ASTM A350 LF2,ASTM A352 LCB/LCC |

| Number Of Way | 2way |

| Brand Name | FALCON |

| Connection Type | Flanged End, Buttweld, Socket weld, Threaded |

| Pressure Rating | ANSI CLASS 150 -2500 |

| Temperature Rating | -40°C TO -269°C |

| Warranty | 24 MONTH |

| Country of Origin | India |

| Product Code | FVFLTS1 |

| Port | JNPT |

| Payment Terms | L/C, D/A, D/P, T/T |

| Delivery Time | 6 WEEK |

| Packaging Details | EXPORT WOODEN BOX |

Falcon is a premier manufacturer specializing in high-performance valves engineered for extreme sub-zero environments. Our low-temperature service valves are designed to maintain bubble-tight shut-off and operational integrity in conditions where standard valves would fail.

1. Valve Types & SizesWe offer a comprehensive range of designs to suit various piping configurations:

-

Gate Valves: For full-flow, low-pressure drop applications.

-

Globe Valves: Ideal for throttling and frequent operation.

-

Check Valves: To prevent backflow in cryogenic lines.

-

Ball Valves: Quarter-turn valves for quick shut-off, featuring cavity pressure relief.

-

Sizes: Available from 1/2" to 24" (larger sizes available upon request).

-

Pressure Classes: ASME Class 150 to 2500.

Cryogenic service requires materials that remain ductile at temperatures as low as -196{°C}.

-

Body/Bonnet: ASTM A351 Gr. CF8/CF8M (Stainless Steel) or ASTM A352 Gr. LCB/LCC or ASTM A350 LF2(Low Carbon Steel).

-

Trim: 316 Stainless Steel with Stellite facing for wear resistance.

-

Seals/Gaskets: PTFE, PCTFE (Kel-F), or Graphite (fire-safe).

-

Extended Bonnet: Essential to keep the packing gland away from the cold fluid to prevent freezing.

Our valves are manufactured in state-of-the-art facilities using precision CNC machining and controlled welding processes.

-

Design: API 600, API 602, API 608, or ASME B16.34.

-

Face-to-Face: ASME B16.10.

-

End Connections: Flanged (ASME B16.5), Butt-weld (B16.25), or Socket-weld.

Every valve undergoes rigorous testing to ensure safety in hazardous environments.

-

Cryogenic Testing: Per BS EN 12567 or MSS SP-134, involving liquid nitrogen cooling to verify seat leakage at service temperatures.

-

Shell & Seat Test: API 598.

-

Fugitive Emissions: ISO 15848-1 to ensure environmental compliance.

Falcon valves are the trusted choice for:

-

LNG (Liquefied Natural Gas): Terminals, carriers, and regasification plants.

-

Industrial Gases: Liquid Oxygen (LOX), Nitrogen (LIN), and Argon (LAR).

-

Aerospace: Launchpad fuel handling systems.

-

Ethylene Plants: Low-temperature petrochemical processing

The most critical component for low-temperature service is the extended bonnet. Falcon’s design ensures that the stem packing remains at an ambient temperature, preventing the packing from freezing and ensuring a leak-proof seal.

Superior Technical Features-

Cavity Pressure Relief: In cryogenic ball and gate valves, trapped liquid can vaporize and create massive internal pressure. Falcon valves feature automatic pressure relief (vent holes or self-relieving seats) to ensure safety.

-

Live-Loaded Packing: We utilize Belleville spring washers to maintain a constant load on the gland packing, compensating for thermal expansion and contraction during temperature fluctuations.

-

Stellite™ Hard Facing: All seating surfaces are hard-faced with Stellite to prevent "galling"—a common issue when metal-to-metal contact occurs at extreme sub-zero temperatures.

-

Anti-Static & Fire-Safe: All designs are inherently anti-static and tested to API 607 standards to ensure performance even in the event of a fire.

We have a particularly strong presence and a deep list of approved vendors in the following regions:

-

Middle East / Gulf: Saudi Arabia (Major supplier to SABIC & Farabi), United Arab Emirates (UAE), Qatar, Kuwait, Oman, and Iraq.

-

Africa: Nigeria, Kenya, Sierra Leone, Tanzania, and South Africa.

-

Southeast Asia & Asia-Pacific: Malaysia, Indonesia, Sri Lanka, Nepal, and Australia.

-

Europe & CIS: United Kingdom, Bulgaria, Turkmenistan, and various CIS nations.

-

Americas: United States, Canada, and Paraguay

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Design | Ball valves, Gate Valves, Globe Valves & Check Valves |

| Seats | Soft or metal seated |

| Construction | One piece body (top, side or end entry), split body (two or three piece), Casting and Forging. |

| Size ANSI | 0,25” - 16” |

| Pressure ANSI | 150 lbs - 4500 lbs |

| Size DN | DN 6 - DN 400 |

| Pressure PN | PN 10 - PN 400 |

| Design temp. | minus 196 C up to 40 C |

| End connections | Flanged, BW, SW, THR, HUB, PE |

| Operated | Lever, gear, actuator |

| Seat materials | Graphite, Devlon, TFM, PTFE, PEEK, POM, PCTFE |

| Hard facing | Various hard facing on ball and seats |

| Options | Extended stem, Extended bonnet, Single or double piston design |

| Design & testing | All available international standards according to API - EN – ISO |

Custom valves manufacturing for Oxygen services

Falcon is one of the leading oxygen service valves manufacturer and exporter in India. Our valves are designed and manufactured against the latest industrial standards with proven designs. For oxygen valve services and applications, limitations are set on sharp edges and the degreasing of valves. We clean all valves according to proven cleaning procedures.

Oxygen applications

- Oxygen valves features

- Minimize sharp edges

- High velocity design features

- Suitable packings

Why choose us

- Commitment

Our valves are designed and manufactured to ensure safety, quality and regulatory compliance of users and patients

- Expertise

We've served industries for over a decade, developing solutions based on your evolving oxygen needs.

- Accreditation and regulation

We help you ensure your facility's medical equipment is serviced and fully compliant with Industries standards

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Temperature Rating | -60 C TO + 450 C |

| Pressure Rating | 150 PSI |

| Connection Type | Flanged |

| Brand Name | FALCON |

| Number Of Way | 2way |

| Material | ALLOY 20,SS904L,HASTELLOY,PFA LINED |

| Valve Size | 1/2" To 36" |

| Type | Safety Valve,Control Valves,Plug Valves,Diaphragm Valves |

| Product Code | FVFPAS1 |

| Port | JNPT |

| Payment Terms | L/C, D/P, T/T |

| Delivery Time | 6 WEEK |

| Packaging Details | EXPORT WOODEN BOX |

At Falcon, we specialize in the engineering and supply of high-performance valve solutions specifically designed for the grueling demands of phosphoric acid production. Handling phosphoric acid is a delicate balance of managing extreme corrosion, abrasive slurries, and scaling—challenges that standard valves simply can’t survive.

Our SpecializationWe don't just provide valves; we provide reliability for the fertilizer and chemical processing industries. Our expertise covers the entire phosphoric acid lifecycle:

-

Corrosion Resistance: Utilizing advanced alloys (such as Alloy 20, Hastelloy, and Duplex steels) and specialized linings to prevent chemical degradation.

-

Slurry Management: Our valves are engineered to handle "green" and "amber" acid streams containing gypsum and other abrasive solids without clogging or eroding.

-

Scale Mitigation: Innovative designs that minimize "dead spaces" where scale buildup typically occurs, ensuring long-term operational efficiency.

| Valve Type | Primary Application | Key Benefit |

| Lined Butterfly Valves | High-volume flow control | Maximum chemical inertness |

| Diaphragm Valves | Slurry and abrasive media | Zero-leakage & easy maintenance |

| Plug & Ball Valves | Isolation services | High-torque reliability in scaling environments |

With decades of field experience, Falcon understands that a valve failure in a phosphoric acid plant doesn't just mean downtime—it’s a safety and environmental risk. We deliver engineered endurance that keeps your plant running smoother, longer.

Building on our general overview, Falcon’s phosphoric acid service valves are manufactured to rigorous technical standards to ensure they withstand the specific chemical and physical stressors of H₃PO₄ production.

Technical Specifications: Phosphoric Acid Series 1. Material Selection (Body & Trim)Phosphoric acid often contains impurities like fluorides and chlorides that can strip away standard protective layers. We utilize high-alloy materials specifically suited for these environments:

-

Super Austenitic Steel: SS 904L and 254 SMO for superior resistance to pitting and crevice corrosion.

-

Specialty Nickel Alloys:Alloy 20 (Carpenter 20), Hastelloy C276, and Incoloy 825 for high-temperature concentrated acid streams.

-

Duplex Alloys: Duplex (UNS S31803) and Super Duplex (UNS S32750) for a high-strength, erosion-resistant solution in slurry lines.

Our valves are designed to meet or exceed international safety and performance benchmarks:

-

Design Standards: API 6D, ASME B16.34, and BS EN ISO 17292.

-

Face-to-Face: ASME B16.10 or DIN EN 558.

-

Flange Dimensions: ASME B16.5 (1/2" to 24") or ASME B16.47 (26" and above).

-

Testing & Inspection: Every valve undergoes hydrostatic and pneumatic testing per API 598 or EN 12266-1 before shipment.

| Feature | Range / Specification |

| Size Range | 1/2” (DN15) to 36” (DN900) |

| Pressure Class | ASME 150#, 300#, 600#, and up to 2500# |

| Temperature | -29°C to +240°C (depending on material/seal selection) |

| End Connections | Flanged (RF, RTJ), Butt-Weld (BW), Socket-Weld (SW) |

To combat the scaling and abrasive nature of phosphoric acid:

-

Soft Seats: Virgin PTFE, Glass/Carbon-filled PTFE, or Devlon V for bubble-tight shut-off.

-

Metal Seats: Hard-faced with Stellite 6 or Tungsten Carbide for slurry-heavy "green acid" applications.

-

Stem Packing: Multi-V-ring live-loaded packing to ensure zero leakage to the atmosphere.

-

Filter Feed Isolation: Designed to handle the high gypsum content without seat "locking."

-

Evaporator Loop: Materials chosen to resist the aggressive corrosion seen in the concentration stages where temperatures rise significantly.

-

Acid Storage & Loading: High-cycle reliability for railcar and tank truck loading stations

| Business Type | Manufacturer, Exporter, Supplier |

| Temperature Rating | -60 C TO + 450 C |

| Pressure Rating | ANSI CLASS 150 -2500 |

| Connection Type | Flanged |

| Brand Name | FALCON |

| Number Of Way | 2way |

| Material | C70600,C71500,S32750,S32760,S31803,S32205,S31254,254 SMO,INCONEL 625,MONEL 400,TITANIUM GR 2 |

| Valve Size | 1/2" To 96" |

| Type | Ball, Gate, Globe, Check, Butterfly, Safety Valve, Control Valves, Plug Valves |

| Product Code | FVFSWS1 |

| Port | JNPT |

| Payment Terms | L/C, D/A, D/P, T/T |

| Delivery Time | 6 WEEK |

| Packaging Details | EXPORT WOODEN BOX |

Engineered for the Elements: Falcon’s Seawater Specialization

Falcon is a global leader in the design and manufacture of high-performance valves engineered specifically for the world’s most demanding seawater environments. With decades of expertise, we provide robust flow-control solutions that eliminate the risks of marine corrosion and material fatigue. From offshore platforms to desalination plants, Falcon ensures operational longevity where others fail.

Falcon Product Portfolio: Seawater & Industrial Valves

Falcon designs and manufactures a comprehensive range of valves and strainers, strictly adhering to international standards such as API, ASME, ANSI, BS, and DIN. Below are the technical details of our core product line:

1. Isolation & Flow Control Valves

| Valve Type | Technical Specifications | Seawater Specialization |

| Gate Valves |

Types: Cast Steel, Forged Steel, Knife Gate Sizes: 1/2" to 48" Class: 150# to 2500# |

Available in Super Duplex (F55) and Titanium for high-pressure isolation in offshore risers. |

| Globe Valves |

Design: Straight Pattern, Y-Type, SDNR Ends: Flanged, BW, SW Operation: Manual, Actuated |

Precision-throttling designs in Nickel Aluminium Bronze (NAB) to resist biofouling and erosion. |

| Ball Valves |

Types: Floating, Trunnion Mounted, 3-Way Design: Fire-safe, Blowout-proof stem Rating: Up to Class 2500 / 6000 PSI |

Metal-seated options in Monel or Hastelloy for abrasive slurry or high-salinity service. |

| Butterfly Valves |

Types: Wafer, Lug, Flanged Design: Double/Triple Offset (TOBV) Sizes: Up to 96" |

2. Specialized & Critical Service Valves

-

Check Valves (Non-Return):

-

Types: Swing Check, Dual Plate, Lift Check, Nozzle Check.

-

Features: Quick-closing to prevent water hammer; essential for seawater injection and ballast systems.

-

-

Safety & Relief Valves:

-

Function: Critical overpressure protection for pressure vessels and pipelines.

-

Materials: Engineered in SS904L and Inconel to maintain spring integrity in corrosive atmospheres.

-

-

Control Valves:

-

Types: Pneumatic or Electric Actuated for precise pressure and flow regulation.

-

Application: Ideal for desalination plants and chemical processing where seawater is the primary media.

-

3. Filtration & Protection

-

Industrial Strainers:

-

Types: Y-Type, T-Type, Basket (Simplex/Duplex), Fabricated Strainers.

-

Details: Heavy-duty mesh liners in Cupro Nickel or Stainless Steel to protect downstream equipment from marine debris.

Technical Summary & Material Standards

Falcon ensures all products meet the rigorous demands of marine and offshore environments through:

-

Manufacturing Standards: Conforming to API 6D, API 600, ASME B16.34, and ISO 9001.

-

Material Grades:

-

Duplex/Super Duplex: ASTM A890 Gr. 4A/5A/6A, ASTM A182 F51/F53/F55.

-

Nickel Alloys: Monel 400, Inconel 625, Hastelloy C276.

-

Exotics: Titanium Gr. 2 & Gr. 5, Nickel Aluminium Bronze (ASTM B148 C95800).

-

-

Testing: 100% Hydrostatic and Pneumatic testing; optional NDT (Radiography, UT, Dye Penetrant) and Pitting Resistance Equivalent Number (PREN) verification.

Seawater Material Specialization & Quality Excellence

At Falcon, the foundation of our seawater specialization is the Science of Corrosion Resistance. Seawater is a living, aggressive medium that causes pitting, crevice corrosion, and biofouling. Our quality process ensures that every valve is metallurgically matched to its specific subsea or splash-zone environment.

The Falcon Advantage: Material Integrity

We utilize High-PREN (Pitting Resistance Equivalent Number) materials to ensure our valves exceed a rating of 40, providing a robust defense against chloride-induced stress corrosion cracking (CSCC).

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | FALCON |

| Material | Alloy 20, SS904L, Hastelloy C276, SS316 |

| Pressure | 150# & 300# |

| Application | Industrial |

| Product Code | FVFSA5 |

| Port | JNPT |

| Payment Terms | L/C, D/A, T/T, Western Union |

| Delivery Time | 6 WEEK |

| Packaging Details | EXPORT WOODEN BOX |

Falcon Sulphuric Acid Valves: Uncompromising Performance for Corrosive Environments Sulphuric acid (H₂SO₄) is one of the most widely used industrial chemicals, integral to processes across the Mining, Petrochemical, Steel, and Fertilizer industries. However, its highly corrosive nature presents significant challenges for valve integrity and operational safety. At Falcon Valves and Flanges Pvt Ltd., we specialize in designing and manufacturing a comprehensive range of Sulphuric Acid Valves engineered to excel in these demanding applications, ensuring long-term reliability and minimizing downtime.

Our extensive portfolio includes all types of valves – from ball and gate to globe, check, and butterfly valves – meticulously crafted to handle various concentrations and temperatures of sulphuric acid. The cornerstone of our offering lies in our precise material selection, leveraging advanced alloys to provide unparalleled corrosion resistance.

The Falcon Advantage: Superior Material Selection for Sulphuric Acid Service Choosing the right material is paramount for safe and efficient sulphuric acid handling. Falcon Valves offers valves manufactured from a range of high-performance alloys, each selected for its specific benefits in resisting sulphuric acid 's corrosive effects:

1. SS316 (Stainless Steel 316):

Benefits: Stainless Steel 316 is a cost-effective and widely used austenitic stainless steel, offering good general corrosion resistance. It performs well in dilute sulphuric acid solutions and at lower temperatures. Its molybdenum content enhances its resistance to pitting and crevice corrosion.

Applications: Ideal for less aggressive sulphuric acid concentrations (up to 20% at ambient temperatures) and where moderate corrosion resistance is acceptable.

2. SS904L (Stainless Steel 904L):

Benefits: SS904L is a super austenitic stainless steel known for its exceptional corrosion resistance, particularly in moderate to high concentrations of sulphuric acid and at elevated temperatures. Its higher content of chromium, nickel, and molybdenum, coupled with copper addition, significantly improves its resistance to uniform corrosion, pitting, and stress corrosion cracking in sulphuric acid environments. It outperforms SS316 in more aggressive conditions.

Applications: Highly recommended for concentrations up to 70% at moderate temperatures, and for various concentrations at ambient temperatures where superior resistance is required. Suitable for critical lines in fertilizer plants, pickling lines in steel mills, and various petrochemical processes.

3. Alloy 20 (Carpenter 20 / UNS N08020):

Benefits: Alloy 20 is a nickel-iron-chromium alloy with additions of molybdenum and copper, specifically designed for excellent resistance to sulphuric acid. It provides superior performance across a wide range of sulphuric acid concentrations and temperatures, including hot and moderately concentrated solutions. Its composition offers outstanding resistance to stress corrosion cracking, pitting, and crevice corrosion in sulphuric acid, as well as other aggressive acid.

Applications: A preferred choice for highly corrosive sulphuric acid applications, especially in the 20-50% range at boiling temperatures, or 85-95% concentrations at lower temperatures. Widely used in the fertilizer industry (e.g., phosphoric acid production), chemical processing, and pharmaceutical applications where robust acid resistance is critical.

4. Hastelloy C276:

Benefits: Hastelloy C276 is a nickel-molybdenum-chromium superalloy with excellent resistance to a wide range of severe corrosive environments, including very aggressive sulphuric acid concentrations, especially at high temperatures and in the presence of impurities or oxidizing agents. It offers exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking. Its versatility makes it the material of choice when other alloys fail.

Applications: Reserved for the most challenging sulphuric service.

| Business Type | Manufacturer, Exporter, Supplier |

| Number Of Flower | Ball Valves, Through Conduit Gate Valves, Check Valves And Control Valves |

| Application | Vinyl Chloride Monomer Service (VCM) |

| Brand Name | FALCON |

| Size | 1/2" to 24" |

| Product Code | FVFVCM1 |

| Port | JNPT |

| Payment Terms | L/C, D/P, T/T |

| Delivery Time | 6 WEEK |

| Packaging Details | EXPORT WOODEN PACKING |

Falcon Valves and Flanges Pvt Ltd. possesses extensive, in-hand experience in designing and manufacturing specialized Vinyl Chloride Monomer (VCM) Service Valves for critical applications within the petrochemical industry. Recognizing VCM as a colorless, highly flammable, and toxic gas that is typically handled as a liquefied gas under pressure, our valves are engineered to manage its unique and challenging properties.

Our VCM valves are precisely manufactured in high-grade materials such as Stainless Steel and Monel, chosen specifically for their excellent corrosion resistance and mechanical integrity in the presence of VCM, which can exhibit corrosive tendencies, especially when moisture is present. Stainless Steel (e.g., 316L) offers robust performance, while Monel (e.g., Monel 400, K500) provides superior resistance to stress corrosion cracking and general corrosion, crucial for applications where extreme purity and long-term reliability are paramount.

Having successfully supplied VCM valves to numerous petrochemical plants, Falcon Valves leverages its deep understanding of VCM 's characteristics – including its low boiling point, high vapor pressure, and potential for polymerization – to deliver solutions that ensure optimal safety, leak-tightness, and operational efficiency. Each valve is designed to withstand the pressures and temperatures inherent in VCM service and undergoes stringent quality control and testing to prevent leaks and ensure reliable flow control in this demanding environment.