sales@fvfindia.com View Mobile Number

Steel Valves

Leading Manufacturers, Exporters and Wholesaler of Alloy 825 Valves, Dual Plate Check Valve, Oxygen Service Valves, Carbon Steel Valves, Stainless Steel Valves, Inconel Valves, Hastelloy Valves, Monel Valves, ball valve, Safety Valves, Control Valves, Butterfly Valve, Forged Steel Valves, SS904L Steel Valves, 254 SMO Steel Valves, Duplex Stainless Steel Valves, Super Duplex Stainless Steel Valves, Alloy 20 Valves and Alloy Steel Valves from Mumbai.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Valves |

| Material | Alloy 825 |

| Color | Metallic |

| Application | Industrial Applications |

| Size | Varies Based On Valve Type |

| Packaging | Standard Packaging |

Alloy 825 Valves are made to work in highly aggressive industrial environments. These products are assured to give outstanding resistance to corrosion and heat. To serve your demands, we at Falcon Valves specialise in manufacturing high-quality Alloy 825 Valves. We promise to give a trustworthy, reliable flow control in applications where conventional valve materials fail.

Alloy 825 Valves an outstanding choice for use in

• chemical processing,

• offshore oil & gas,

• pollution control,

• nuclear fuel reprocessing,

• Marine applications.

Falcon’s Alloy 825 Valves are offered in different kinds, like gate, globe, check, and ball valves. All kinds are rightly engineered to withstand corrosive fluids and work under high pressure and temperature.

Why Choose Falcon Valves for Alloy 825 Valves?

• Years of industry experience - Decades of proficiency in designing field metal valves for harsh environments.

• Top material choice – Just certified Alloy 825 materials are utilised, ensuring reliability and fulfilment.

• Customisation Capability – personalised solutions for pressure size, rating, end connection, and valve design.

• Advanced Manufacturing – CNC precision-machining and in-house excellence testing for leak-proof and true results.

• On-Time Delivery – Streamlined manufacturing and logistics to meet your project deadlines proficiently.

• Compliant with worldwide Standards – Valves are properly tested to meet ASME, API, and ASTM standards.

• Technical assistance and paperwork – Get assistance from design to post-installation, like the material test certificates and examination reports.

Prime features of Alloy 825 Valves

Superior Corrosion Resistance

•It is quite resistant to phosphoric, sulfuric, and nitric acids and seawater. It turns perfect for chemical and marine setups.

Excellent Mechanical Strength

•It is about to keep the high tensile strength and dimensional stability under pressure and temperature distinctions.

Chloride Stress-Corrosion Resistant

•It is effective in chloride-rich environments where other materials are prone to cracking or ruin.

High-Temperature Capability

•Appropriate for the elevated temperature services without compromising performance.

Highly durable and long-lasting

•Low wear and tear, even in callous operating conditions, leads to reduced protection and extended service life.

Flexible Application

• Ideal for industries like petrochemical, fertiliser, water treatment, oil & gas, and pollution control systems.

Invest in reliability and performance with Falcon’s Alloy 825 Valves – the favored choice for severe-service flow control.

If you are interested in our products and wish to place order, just contact our team. We also accept the customized orders from the side of the customer. Contact us now for more information.

| Business Type | Manufacturer, Exporter, Supplier |

| Certification | API |

| End Connection | Flanged |

| End Connection Standard | ASME B16.5 |

| Spring Material | Inconel |

| Pressure Rating | ANSI CLASS 150 -2500 |

| Connection Type | Flanged, Wafer, Hub |

| Brand Name | FALCON |

| Structure | 1war |

| Valve Size | 48 Inch |

| Material | Stainless Steel, Metal, Carbon Steeel |

| Color | White, Sky Blue, Blue |

| Application | Water Fitting, Oil Fitting, Gas Fitting |

| Feature | Investment Casting, Durable, Casting Approved, Blow-Out-Proof |

| Country of Origin | India |

| Type | Dual Plate Check Valve |

| Condition | New |

| Power | Manual |

| Pressure | High Pressure, Medium Pressure |

| Appication | Oil and Gas, Petrochemical, Pipelines and Petrochemical plants |

| Material Grade | Duplex Stainless steel, Super Duplex Stainless Steel, Nickel Aluminum Bronze, Inconel, Monel, Hastelloy C276, Titanium, Alloy 20, SS904L, LTCS, CS, SS |

| Size Range | 2" to 96" |

| Payment Terms | L/C, T/T |

| Delivery Time | 6 week |

| Packaging Details | Export wooden packing |

Dual Plate Check Valves

In present flow systems, space always remains restricted, and performance cannot be compromised. If you are looking for the right solution, get Dual Plate Check Valves. Engineered for well-organised non-return operation, these valves prevent reverse flow and water hammer in pipelines while keeping a compact and lightweight design. At Falcon Valves, our Dual Plate Check Valves merge precision durability, engineering, and high-performance operation to make sure your system runs safely and professionally.

Our valves feature two spring-loaded plates that open with ahead flow and automatically close against backflow. It gives faster shut-off and minimal pressure drop. If it is water, gas, steam, or industrial fluids, Falcon’s Dual Plate Check Valves are designed to manage demanding conditions in industries like power generation, oil & gas, chemical processing, marine and HVAC.

Top features of Falcon Dual Plate Check Valves

- Get the Space-Saving Compact Design

With a wafer-thin outline, our valves need negligible installation space, making them suitable for systems with limited room.

- Low Pressure Drop

The streamlined body and proficient plate mechanism decrease turbulence and ensure minimal pressure loss, boosting the overall flow performance.

- Non-Slam Closure Mechanism

The spring-loaded plates make sure a fast, silent end to avoid water hammer, reducing wear and tear on piping systems.

- Corrosion-Resistant Stuff

Our products are made from high-quality carbon steel, stainless steel, and other durable alloys to manage corrosive fluids and harsh environments.

- Flexible Compatibility with Media

It is just right for water, oil, steam, gas, and chemical applications, giving versatility across industrial and commercial sectors.

- Horizontal & Vertical Installation

Planned to function efficiently in both horizontal and vertical pipelines, we offer flexible installation options.

- Long Service Life

Planned with minimal moving parts and precision-engineered components to present reliable performance and extended prepared life.

- Broad Range of Sizes & Pressure Ratings

We offer in multiple diameters and pressure classes, catering to different flow requirements.

- Follow up with International Standards

It is manufactured according to API 594, ASME B16.34, and other worldwide norms for quality, dependability, and safety.

Why Choose Falcon Valves for Dual Plate Check Valves?

Years of Engineering Proficiency

Falcon Valves has built a reputation for outstanding, delivering unfailing flow control solutions, reliable by industries globally.

Precision Manufacturing

Every valve is made with advanced CNC technology and undergoes strict quality checks to meet global benchmarks.

Customization Available

Do you need a particular size, pressure rating, or material? We offer customised solutions to fit your exact system demand.

Get easy and fast support.

We offer quick dispatch, outstanding technical support, and post-sales service to keep your systems running without any holdup.

Find eco-friendly solutions.

Our valves are planned for energy efficiency and system optimisation. It is about to contribute to lower operational costs and reduced emissions.

If you're planning to build a new system or upgrade the present one, Dual Plate Check Valves offered at Falcon is ready to deliver the compact design, silent process, and robust performance your operations demand.

Trust Falcon Valves – where modernism requires reliability in every flow.

Contact us now to request a quote or travel around custom valve solutions personalised to your industry.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Design | Ball valves, Gate Valves, Globe Valves & Check Valves |

| Seats | Soft or metal seated |

| Construction | One piece body (top, side or end entry), split body (two or three piece), Casting and Forging. |

| Size ANSI | 0,25” - 16” |

| Pressure ANSI | 150 lbs - 4500 lbs |

| Size DN | DN 6 - DN 400 |

| Pressure PN | PN 10 - PN 400 |

| Design temp. | minus 196 C up to 40 C |

| End connections | Flanged, BW, SW, THR, HUB, PE |

| Operated | Lever, gear, actuator |

| Seat materials | Graphite, Devlon, TFM, PTFE, PEEK, POM, PCTFE |

| Hard facing | Various hard facing on ball and seats |

| Options | Extended stem, Extended bonnet, Single or double piston design |

| Design & testing | All available international standards according to API - EN – ISO |

Custom valves manufacturing for Oxygen services

Falcon is one of the leading oxygen service valves manufacturer and exporter in India. Our valves are designed and manufactured against the latest industrial standards with proven designs. For oxygen valve services and applications, limitations are set on sharp edges and the degreasing of valves. We clean all valves according to proven cleaning procedures.

Oxygen applications

- Oxygen valves features

- Minimize sharp edges

- High velocity design features

- Suitable packings

Why choose us

- Commitment

Our valves are designed and manufactured to ensure safety, quality and regulatory compliance of users and patients

- Expertise

We've served industries for over a decade, developing solutions based on your evolving oxygen needs.

- Accreditation and regulation

We help you ensure your facility's medical equipment is serviced and fully compliant with Industries standards

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Cast Gate Valve |

| Material | Cast Steel |

| Application | Water Fitting |

| Weight | 10-15kg |

| Feature | Durable, Good Quality |

| Condition | New |

We at Falcon Valves & Flanges Pvt Ltd are dedicated to providing our clients with a wide range of high-quality Cast steel gate valves. These valves are available in a variety of specifications and can also be customised. These are made using high-quality stainless steel, iron, and other materials in accordance with the parameters shown.

A valve is a piece of equipment that governs, directs, or determines the flow of a fluid (gases, liquids, fluidized solids, or slurries) by opening, closing, or partially obstructing different passageways. We manufacture these valves in a variety of sizes, measurements, component grades, and compression capacities. Water management, petroleum & gas, electric utilities, oil and natural gas, and other low-pressure implementations are among the applications.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Stainless Steel Gate Valve |

| Material | Stainless Steel |

| Color | Grey |

| Feature | Durable, Good Quality |

| Condition | New |

| Country of Origin | India |

We at Falcon Valves & Flanges Pvt Ltd are one of the most reputable Stainless steel gate valve Manufacturers in India. The Stainless steel gate valves are suitable for different types of industrial applications due to its high sturdiness, tensile strength, and resistance to adverse conditions. Stainless steel gate valve is also accessible in various of sizes and dimensions that meet the specifications. Because there are few moving parts, our specially designed S valve operating system will ensure shock-proof and stress-free operation, as well as longer life.

The range is made of high-quality materials such as stainless steel, cast carbon steel, and forged steels, among others, and is extremely durable and simple to use. It has a minimalistic size, and the gate has a knife edge to cut through fibrous medium.

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Water |

| Material | Inconel |

| Finishing | Polished |

| Cast UNS | N06040 |

| Size | ½ to 24 Inch |

| Class | 150 to 2500 |

Inconel 600 (UNS N06600) valves are designed and manufactured in applications where high temperature and corrosion resistance is required.This nickel alloy is developed for service tempertures from cryogenic to elevated temperatures in the range of 1100°C. It also provides excellent corrosion resistant to organic and inorganic compounds, chloride ion stress corrosion cracking and alkaline solutions.

Inconel 600 Material grades

- Cast ASTM : A494 Gr CY40

- Cast UNS : N06040

- Wrought UNS : N06600

- Wrought Grade : Inconel 600

Specifications

- Size: ½” to 24”

- Class: 150# to 2500#

Following type of Valves are manufactured by Falcon

- Inconel 600 Gate valves

- Inconel 600 Globe valves

- Inconel 600 check valves

- Inconel 600 Ball valves

- Inconel 600 butterfly valves

- Inconel 600 Strainers

- Inconel 600 Plug valves

Characteristics of Inconel 600

Inconel 600 is resistant to wide range of corrosive media. It’s non-magnetic and has excellent mechanical properties under wide range of temperatures

Application of Inconel 600 valves

- Oil and Gas Refineries

- Chemical plants

- Paper and Pulp industries

- Food Processing

- Petrochemical plants

- Fertilizer plants

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Metal |

| Casting Grade | A494 CW-12MW |

| Cast UNS | N30002 |

| Wrought UNS | N10276 |

| Size | ½ to 24 Inch |

| Finishing | Polished |

| Application | Water |

Hastelloy C276 Valves

In case some industrial systems face highly corrosive chemicals, high temperatures, and extreme environments, only the most resilient materials can withstand the challenge. Hastelloy C276 Valves offered at Falcon Valves are made to answer the conditions. Made with one of the most corrosion-resistant alloys offered - Hastelloy C276, our valves are assured to give better resistance to oxidising and reducing agents.

These properties make it suitable for

- Chemical processing,

- Marine,

- Oil & gas,

- Pollution control sectors.

At Falcon Valves, we give precision-engineered Hastelloy C276 Valves that are designed to perform dependably under pressure. We make sure to give a long service life and the least maintenance. If you are handling concentrated acids, brines, or oxidants, our valves keep structural integrity and tight sealing in the meantime.

Why Choose Hastelloy C276 Valves offered at Falcon Valves?

- Premium-Grade Stuff

We make use of the certified Hastelloy C276 alloy that resists corrosion in both oxidising and reducing environments. It can react with chlorine gas and strong oxidants such as ferric and cupric chlorides.

- Better Engineering Standards

Every valve is made with proper testing and precision to global standards, which include ASME, API, and NACE MR0175.

- Broad Application Compatibility

Our products are well-trusted by industries that need to work with sulfuric, hydrochloric, nitric, and acetic acids.

- Work with High Temperature & Pressure

Our products are suitable for use even under high-pressure systems. It can suitably work in temperatures up to 1040°C. It will never lose mechanical strength.

- Resistant to Corrosion & Pitting

Our valve is outstanding in resistance to crevice corrosion, pitting, and stress corrosion cracking in a broad range of chemical environments.

- Customized Solutions

Our valves are available in multiple designs i.e ball, gate, globe, check, and butterfly valves. It is made with customised end connections and pressure ratings.

- Zero Leak Performance

It is made for the utmost sealing, even under fluctuating pressures and chemical loads.

Different kinds of Hastelloy C276 Valves are offered

Hastelloy C276 Ball Valves

- It is made for the smooth shut-off in acidic chemical pipelines.

Hastelloy C276 Gate Valves

- They are made for the full-flow applications where the least pressure drop is necessary.

Hastelloy C276 Globe Valves

- It allows the precise throttling and flow control of forceful fluids.

Hastelloy C276 Check Valves

- It avoids the backflow in corrosive process lines. It ensures the one-way flow.

Hastelloy C276 Needle Valves

- It is suitable for metering applications that demand fine flow regulation in serious systems.

Industries That Focus on Our Hastelloy Valves

- Chemical Processing Plants

- Pharmaceutical & Biotech Units

- Oil Refineries & Offshore Drilling

- Pulp & Paper Industry

- Desalination & Wastewater Treatment

- Nuclear and Power Generation

Falcon Valves merges corrosion science, advanced engineering, and years of manufacturing expertise to present Hastelloy C276 Valves that stand the test of time in the harshest industrial setups.

If you are interested in buying Hastelloy C276 Valves and have more questions, contact our team now.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Monel Valve |

| Material | Monel |

| Condition | New |

| Casting Grade | A494 M35-1 |

| Wrought Uns | N04400 |

| Cast Uns | N24135 |

monel 400 (uns n04400) is resistant to seawater and steam at high temperatures as well as to salt and caustic solutions. falcon monel 400 valves is used in hydrochloric and hydrofluoric acid environments.

monel 400 material grades

- casting grade: a494 m35-1

- wrought uns: n04400

- cast uns: n24135

- specifications

- size: ½” to 24”

- class: 150# to 2500#

following type of valves are manufactured by falcon

- monel 400 gate valves

- monel 400 globe valves

- monel 400 check valves

- monel 400 ball valves

- monel 400 butterfly valves

- monel 400 strainers

- monel 400 plug valves

application of monel 400 valves

- seawater applications

- chemical plants

- gasoline lines

- oil refineries

- boiler feed water lines

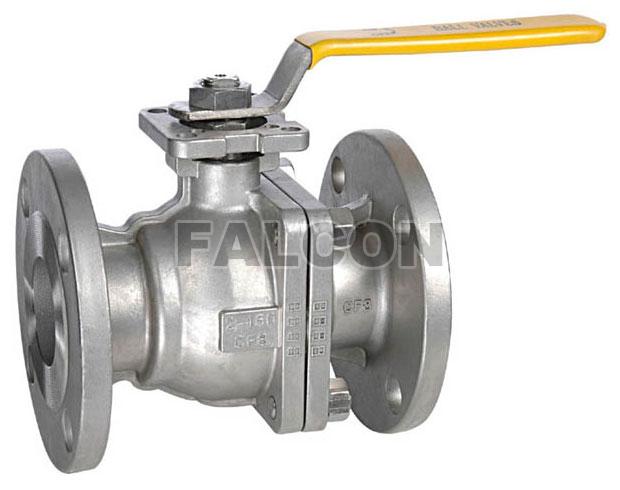

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Industrial |

| Pressure | High Pressure |

| Material | Metal |

| Packaging Type | Box |

| Finishing | Polished |

| Temperature | -46°c~+600°c |

Ball Valves

When every drop counts and flow control should be flawless, Ball Valves from Falcon Valves are ready to give matchless performance. It is best known for their level of reliability, easy to work and tight shut-off capabilities. Our ball valves are wonderful options for different industries like

- Oil & gas,

- Power generation,

- Water treatment,

- Chemical processing.

If you’re handling high-pressure gases or even corrosive liquids, our Ball Valves promises to give an ideal balance of safety, strength, and seamless flow control. Made with the advanced technology and crafted from premium stuff, the product makes sure for the best performance in the highly demanding conditions.

Falcon Valves is not just deal with the valves – but we give the best engineered solutions that power your systems with efficiency, confidence, and durability.

Key Features of Falcon Ball Valves

Trustworthy Shut-Off Performance

Our Ball Valves present a tight and safe seal even in high-pressure setups. It makes sure for the complete shut-off without leaks.

Full Port and Reduced Port choices

Select in the middle of the full port valves for least pressure drop or reduced port valves for saving the space and budget friendly solutions.

Robust Construction

It is prepared from the top quality stuff like carbon steel, brass, stainless steel, and forged alloys to give superior strength and corrosion resistance.

Blowout-Proof and Fire-Safe Designs

Better safety features make our Ball Valves appropriate for critical applications, ensuring guard against fire and internal pressure build-up.

Offered in Multiple Configurations

We provide two-piece, three-piece, and flanged ball valves with the best of the end connections such as socket weld, butt weld, threaded, and flanged ends.

Smooth Operation with Low Torque

Planned for ease of operation, our valves provide smooth rotation with low torque needs, making them appropriate for both manual and automated systems.

Broad Pressure and Temperature Range

Our Ball Valves can handle extreme operating conditions, starting from cryogenic to high-temperature setups, with pressure ratings up to Class 2500.

Minimal Maintenance needs

With fewer moving parts and wear-resistant elements, Falcon Ball Valves ensure long service life and reduced downtime.

Standards & Certifications

Designed and manufactured to meet global standards such as API 6D, ASME B16.34, ISO 9001, and fire-safe compliance.

Industries Served

It is widely used in the

- oil & gas,

- petrochemical,

- HVAC,

- power generation,

- water treatment,

- marine,

- food processing,

- Pharmaceutical sectors.

Why Choose Falcon Valves?

Falcon Valves with years of experience and a strong standing in valve manufacturing is committed to give the better performance, quality, and customer satisfaction. Our Ball Valves are rigorously tested to ensure they meet strict quality and security benchmarks before reaching your hands.

Whether, you require a valve for high-pressure fluid control or a dense solution for a tight system layout, Falcon Ball Valves give the best of the effectiveness and reliability in the supply of the product. .

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Safety Valves |

| Material | Brass,Carbon Steel,Steel |

| Certification | ISO 9001:2008 Certified |

| Application | Gas Fitting,Oil Fitting,Water Fitting |

| Weight | 1kg |

| Color | Silver |

| Feature | Blow-Out-Proof,Casting Approved,Corrosion Proof |

| Condition | New |

| Pressure | 150# to 2500#, PN 6 to PN 100 |

| Country of Origin | India |

| End Connection | Flanged,Screwed,Socket Weld Ends |

| Brand Name | FALCON |

| Structure | CASTING AND FORGING |

| Temperature Of Media | 0 TO 550 C |

| Nominal Diameter | DN 10 – DN 600 I 1/2 |

| Temperature | -268 °C to 540 °C I -450 °F to 1000 °F |

| Actual Orifice | 14mm – 161.5mm I 0.551 in – 6.36 in |

| Actual Orifice Area | 154mm2 – 20,485 mm2 I 0.239 in2- 31.75 in2 |

| Flange Connections | ANSI B16.5, EN 1092, JIS, BS10 |

| Body Material | Bronze, Cast Iron, SG Iron,Carbon steel, Stainless steel, Alloy steel, Nickel Alloys, Monel, Inconel, Hastelloy, Alloy 20, Duplex and Super duplex |

| Seat | EPDM, Viton, Nitrile, Stainless steel and Stellite |

Safety Relief Valve

Are you looking for the best quality of the safety relief valve? YES. We at Falcon Valves are here with the best quality of Safety Relief Valve. We have designed our products to withstand the dangers of overpressure. It is widely used in different applications such as oil and gas, chemical manufacturing, and steam systems.

Our best quality valves are helpful in automatically releasing pressure. It is helpful to work within the predetermined limit. Therefore, it avoids unwanted accidents, failure of equipment, or catastrophic damage. At Falcon Valves, we are proud to give the high-performance Safety Relief Valves that merge precision, durability, and fulfillment with global standards.

Prime specifications associated with Falcon Safety Relief Valves:

Automatic Pressure Release:

The valve opens when the pressure of the system exceeds the specific limit, make sure to have managed discharge and avoid unsafe conditions.

Right Resealing:

Once normal pressure is restored, the valve reseats strongly, reducing the process fluid loss and maintaining the efficiency of the system.

Used in different applications

It is suitable for use in different industries like oil & gas, power generation, petrochemical, water treatment, and food processing.

Assured for the Robust Construction:

It is made from corrosion-resistant materials like stainless steel, bronze, and other high-grade alloys for long-lasting performance in a highly demanding setup.

Offered in different Configurations:

Make a selection from spring-loaded or even pilot-operated valves with diverse inlet/outlet sizes, pressure ratings, and end connections.

Follow up on the Global Standards:

Properly designed and tested product as per the ASME Section VIII and API standards. They make sure for the best level of the reliability, safety, and regulatory compliance.

Leak-Proof Performance:

Each valve is precision-tested to promise leak-tight sealing and smooth functioning even under fluctuating pressures.

Get the customised choices:

Falcon provides customised valve solutions according to the operating conditions and system demands.

Low Maintenance:

It is made for minimal wear and tear, resulting in reduced downtime and maintenance costs.

By installing Falcon’s Safety Relief Valves, Falcon can keep you confident, mind, regulatory compliance, and the long-term security of your operations. Protect your people, processes, and machines with reliable overpressure protection engineered by one of the industry's most reliable valve manufacturers - Falcon Valves.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Metal |

| Application | Liquid Control |

| Color | Dark-Golden |

| Feature | Durable |

| Pattern | Plain |

| Automation Grade | Manual |

Pressure Reducing Control Valve is a device that controls the flow of air, liquid, or whatever other fluid in a process to minimize pressure. Falcon Valves & Flanges Pvt Ltd is a leading manufacturer and supplier of various types in a variety of applications, including the Pressure Reducing Check Valve.

Our pressure control valves at Falcon Valves & Flanges Pvt Ltd are intended to provide customizable pressure control and restricting functions. As a reputable pressure control valve manufacturer, we serve the nation's major manufacturing markets. Our extensive product line contains hydraulic pressure control valves in a range of patterns as well as process control valves, which would be applicable to a wide range of uses.

| Business Type | Manufacturer, Exporter, Supplier |

| Condition | New |

| Finishing | Polished |

| Material | Metal |

| Application | Water |

| Product Type | Butterfly Valves |

| Temperature Range | -20oC to 180oC |

We manufacture, export and supply the most comprehensive range of Butterfly Valve to suit a wide range of industrial applications. The Butterfly Valve can seamlessly be integrated with a consistent range of manual, electrical, pneumatic, hydraulic actuators to create complete flow control packages. The Butterfly Valve temperature range of from -50oC to +500oC. Butterfly Valve is produced by employing the best raw materials, carefully selected, correctly identified and analyzed. The machining is carried out with the aid of the latest type equipment according to the most up-to-date methods.

| Business Type | Manufacturer, Exporter, Supplier |

| Size | 15mm – 50mm |

| Shell (Hydrostatic) | 104 |

| Seat (Air) | 5.5 |

| Finishing | Polished |

| Weight | 10-15kg |

| Condition | New |

Forged Steel Valves – Made to Endure and Engineered to Perform

In the highly demanding industrial environments where temperature, pressure, and reliability are preset, Forged Steel Valves work out as the real solution. At Falcon Valves, we bring you a top range of Forged Steel Valves that convey unmatched power, precision control, and long-lasting performance in every application.

Made with top-grade forged steel, these valves present superior mechanical properties and outstanding resistance to thermal fatigue and corrosion. Falcon’s Forged Steel Valves are made for high-pressure steam, aggressive chemicals, or high temperatures.

Why select Falcon Forged Steel Valves?

Outstanding Strength & Durability

Forged construction ensures grain refinement and structural reliability, making the valves suitable for the critical and high-pressure functions.

Leak-Proof Sealing Technology

Made for the tight shut-off with precision-machined elements that avoid leakage even under the harsh operating conditions.

Broad application Spectrum

It is just suitable for the

- Power plants,

- Oil & gas refineries,

- petrochemicals,

- Chemical processing,

- Marine,

- Offshore platforms.

Different types of valves

It is offered in

- Gate Valves,

- Globe Valves,

- Check Valves

All three are made with forged steel to meet definite industrial needs.

Pressure & Temperature Resilience

- All are made to perform flawlessly in high-pressure and high-temperature conditions without compromising on control or safety.

Corrosion & Erosion Resistance

- It is just appropriate for the aggressive media due to corrosion-resistant alloys and robust surface finishes.

Standard Compliance

- All products are made according to standards set by ASME, API, and BS standards to ensure safety, quality, and global approval.

Compact Design, better Efficiency

Forged steel allows for the compact construction with the same actions as bulkier alternatives, saving space without compromising purpose.

Personalized Configurations

It is being offered in different sizes, pressure classes, and end connections to suit your system demands.

At Falcon Valves, our Forged Steel Valves symbolise more than simple components. They are assured of quality, reliability, and operational security. Trusted by top engineers across the globe, our valves are tested for survival and built for precision.

Ready to improve your system with power you can count on?

Explore our full range of Forged Steel Valves now and experience the Falcon benefit.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Stainless Steel |

| Application | Water Fitting |

| Color | Silver |

| Feature | Good Quality |

| Condition | New |

| Size | ½ to 24 Inch |

SS904L Valves

If your industry operation demands superior corrosion resistance, mainly in acidic and chloride-rich environments, SS904L Valves are the right option. We at Falcon Valves offer the best quality of SS904L Valves. Our products are prepared from high-alloy austenitic stainless steel, and SS904L valves are planned to deliver outstanding performance. We make sure to give highly durable and safe solutions in demanding industrial applications.

At Falcon Valves, we manufacture and provide top-quality SS904L Valves that meet global standards and are broadly used across industries like chemical processing, oil & gas, pharmaceutical, and marine engineering. Our valves present wonderful resistance to sulfuric acid and other aggressive agents. It makes them an important component for highly corrosive environments.

Prime features of SS904L Valves

- High Corrosion Resistance

SS904L is prominent for its outstanding resistance to strong reducing acids and chloride-induced pitting and stress corrosion cracking.

- Better Mechanical Properties

The alloy keeps high strength and hardiness even in cryogenic and high-temperature settings.

- Non-Magnetic in All Setup

It stays completely non-magnetic, making it appropriate for sensitive applications like the magnetic and electronics fields.

- Long Extended Service Life

With outstanding resistance to oxidation and corrosion fatigue, SS904L valves need the least maintenance over extended operational periods.

- Offered in a wide range of Valve Types

We offer Ball, Gate, Globe, Check, and Butterfly valves in SS904L construction for a broad variety of applications.

Applications of SS904L Valves

- Chemical & Petrochemical Plants is quite appropriate for the systems handling phosphoric, sulfuric, and acetic acids.

- Oil & Gas Industry is suitable for offshore platforms and refineries where saline and corrosive environments are quite common.

- Pharmaceutical Manufacturing – ensure the purity and reliability.

- Marine Engineering works as reliably in saltwater settings and ballast systems.

- It is widely used in waste treatment plants to withstand harsh chemicals.

Why Choose Falcon Valves?

Falcon Valves is dedicated to giving top-tier industrial valve solutions that merge performance, durability, and cost-efficiency. Our SS904L Valves are made by following ASTM, ASME, and other global standards. We follow up the strict testing to ensure trustworthiness in extreme environments.

We offer personalised options, faster delivery, and technical support to meet the precise needs of your operation. If you need standard or custom-engineered SS904L valve solutions, we are your trusted partner in the industry.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Stainless Steel |

| Application | Water Fitting |

| Color | Grey |

| Condition | New |

| Pressure | High, Low, Medium |

| Size | ½ to 24 Inch |

254 SMO (CK3MCuN) is a high-alloy austenitic stainless steel developed for use in seawater and other chloride containing fluids. Falcon 254 SMO valves are designed with a combination of high impact toughness resistance to chloride stress corrosion (SCC), and pitting and crevice corrosion with strength that is twice that of SS316/SS304 stainless steel.

Casting Grade : A351 CK3MCuN

Forging Grade : A182 F44

Wrought UNS : S31254

Cast UNS : J93254

Specifications

- Size: ½” to 24”

- Class: 150# to 2500#

Following type of Valves are manufactured by Falcon

- 254 SMO Gate valves

- 254 SMO Globe valves

- 254 SMO check valves

- 254 SMO Ball valves

- 254 SMO butterfly valves

- 254 SMO Strainers

- 254 SMO Plug valves

Characteristics of 254 SMO valves

254 SMO has a very low carbon content. Pitting resistance equivalent number (PREN) is above 42.5 hence it provides good corrosion resistance in water containing chlorides.

Application of 254 SMO valves

- Seawater lines

- Desalination plants

- Oil refineries distillation columns

- Food industries

- Chemical plants

- Paper and Pulp industries

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Duplex 2205 Stainless Steel |

| Type | Valves |

| Size Range | ½ |

| Pressure Class Range | 150# To 2500# |

| Color | Metallic |

| Resistance | Chloride Pitting And Crevice Corrosion |

| Strength | High |

| Ductility | Excellent |

| Pitting Resistance Equivalent (PREN) Range | 28-38 |

| Applications | Chemical Industries,Oil And Gas Explorations, Etc |

Duplex Stainless Steel Valves

Duplex Stainless Steel Valves are suitable for different industries. It ensures the best performance, reliability, and corrosion resistance. Our valves are engineered using duplex stainless steel, a metallurgical mixture of austenitic and ferrite structures, giving the best of both worlds. It ensures high strength and outstanding resistance to a broad range of corrosive environments.

At Falcon Valves, we produce and supply top-grade Duplex Stainless Steel Valves designed to meet demanding industrial setups.

We are serving the demands of different industries like

- Oil & gas sector,

- chemical processing plants,

- desalination units,

- offshore platforms

Our valves are built to bring long-term effectiveness, leak-proof sealing, and mechanical toughness.

Prime Features of Duplex Stainless Steel Valves

- Outstanding Corrosion Resistance

Our valves give outstanding resistance to stress corrosion cracking, pitting, and crevice corrosion. We make sure of the chloride-rich environments and chemical experience.

- High Toughness and Strength

It gives about double the strength of regular austenitic stainless steels, ensuring structural stability under high pressure and temperature.

- Ensures better performance even in Harsh Environments

It is just appropriate for the seawater, brine, acidic, and caustic applications due to the better material composition.

- Broad range of Valve Types

It is offered in Ball, Gate, Globe, Check, and Butterfly configurations to suit different industrial flow control systems.

- Low Thermal Growth and High Conductivity

Get better dimensional consistency during thermal cycling and boost the regulation of flow.

Applications of Duplex Stainless Steel Valves

- For the Oil & Gas Industry, it is ideal for offshore drilling, pipelines, and refining units.

- For the desalination Plants, it ensures the corrosion-free operation in saltwater treatment systems.

- In the industry of Chemical & Petrochemical, it can be harsh acids and aggressive chemicals.

- For the Pulp & Paper Industry, it manages the chloride-laden pulp liquors and bleaching agents.

- For proper Power Generation, it is used in the cooling systems and turbine operations under tremendous conditions.

Why Choose Falcon Valves for Duplex Stainless Steel Valves?

If you are interested in buying the Duplex Stainless Steel Valves, we at Falcon Valves give high priority to the best quality, durability, and performance. Our Duplex Stainless Steel Valves are manufactured by following the international standards such as ASTM, ASME, and API. Every valve is properly tested for strength, leakage, and resistance.

We also present customised valve solutions to match your specific application and ensure the flawless integration into your existing systems.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Super Duplex Stainless Steel |

| Type | Gate Valves,Globe Valves,Check Valves,Ball Valves,Butterfly Valves |

| Size Range | ½” To 48” |

| Pressure Class Range | 150# To 2500# |

| Corrosion Resistance | High Resistance To Uniform Corrosion To Organic And Inorganic Acids |

| Chloride Stress Corrosion Cracking Resistance | High |

| Pitting And Crevice Corrosion Resistance | Better Than Standard Stainless Steel |

| Applications | Desalination Plant,Chemical Industries,Marine Industries, Etc |

Super Duplex Stainless Steel Valves

There are several industries where standard valves fall short under extreme pressure, temperature, and corrosion. How can you handle the conditions? Well, we at Falcon Valves have a real solution for you. We have the best quality of Super Duplex Stainless Steel Valves. Made with the best performance Super Duplex alloys, our valves present unparalleled strength, superior corrosion resistance, and outstanding durability. It works even in the harshest conditions.

At Falcon Valves, we give a premium selection of Super Duplex Stainless Steel Valves designed to answer the strict demands of chemical, petrochemical, marine, and offshore industries. Our valves are suitable for applications where failure is not an option and long-term performance is important.

Prime Features of Super Duplex Stainless Steel Valves

- Find the unmatched strength

Super Duplex grades give nearly twice the yield power of predictable austenitic stainless steels. It turns the valves highly resistant to mechanical pressure.

- Superior Corrosion Resistance

Outstanding resistance to pitting, crack corrosion, and chloride-induced stress corrosion cracking is suitable for seawater and forceful chemical environments.

- Outstanding Weldability & Fatigue Potency

We make sure of the leak-free, trustworthy joints and the most favourable performance under cyclic loads and thermal pressure.

- Extended Service Life

It is about to cut down the maintenance costs and increase operational lifespan. It is even suitable for high-salinity or acidic setups.

- Offered in different Configurations

We offer Ball, Gate, Globe, Check, and Butterfly valve types for a broad range of industrial applications.

Applications of Super Duplex Stainless Steel Valves

- In the Marine & Offshore industry, it is used in ballast control, seawater injection systems, and riser valves.

- In the industry of Oil & Gas Exploration, it is suitable for subsea installations, pipelines, and refineries.

- For the chemical & petrochemical processing, it is widely used in acidic compounds and reactive fluids.

- Desalination Plants are suitable for brine filtration and high-pressure saltwater processes.

- In the field of Power Generation, it is just appropriate for cooling systems and high-temperature steam circuits.

Why should you choose Falcon Valves?

To give the best product, Falcon Valves is a reliable name in providing precision-engineered flow control solutions. Our Super Duplex Stainless Steel Valves are traditional to global quality standards, including ASTM, ASME, and API. It makes sure to give peak performance under serious conditions.

Each valve is carefully tested for corrosion resistance, pressure tolerance, and mechanical integrity. We also offer custom-made solutions according to the application requirements, ensuring a suitable fit for your systems.

Discover the complete range of Super Duplex Stainless Steel Valves and contact us for professional support and competitive pricing. Contact us now for more information.

| Business Type | Manufacturer, Exporter, Supplier |

| Number Of Way | 2way |

| Voltage Range | 230 V AC |

| Diameter (mm) | 1/2" to 24" |

| Warranty | 2 Year |

| Finishing | Polished |

| Condition | New |

| Material | Alloy 20 Valves |

| Type | Alloy Valves |

| Cast ASTM | A351, A743, A744 |

| Wrought Grade: | 20Cb-3 |

| Wrought UNS | N09020 |

| Cast UNS | N08007 |

| Forging Grade | A182 F20 |

| Casting Grade | ASTM A351 CN7M |

| Size | ½" to 24" |

| Class | 150# to 2500# |

| Country of Origin | India |

| Major Export countries | Saudi Arabia, UAE, USA, UK, France, Germany, Japan, Nigeria, Iraq, Egypt |

| Product Code | FVFA20 |

| Port | JNPT |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union |

| Delivery Time | 6 WEEK |

| Packaging Details | EXPORT WOODEN BOX |

Alloy 20 Valves

Are you dealing with highly corrosive chemicals such as sulfuric acid, nitric acid, and chlorides? Surely, your industrial system demands a robust and trustworthy solution. Alloy 20 Valves give the perfect balance of mechanical strength, and cost-efficiency. We have prepared a high-performance austenitic alloy primarily composed of chromium, molybdenum, nickel, and copper. Our valves are engineered to withstand aggressive setups where conventional stainless steel valves would fail.

At Falcon Valves, we present a top range of Alloy 20 Valves that are perfect for critical operations. We serve

- chemical processing,

- petrochemical,

- food & beverage,

- pharmaceutical,

- Marine industries.

Our valves are made with precision and tested under strict quality standards to ensure performance, security, and long-term service life.

Prime Features of Falcon’s Alloy 20 Valves

- Better Resistance to Sulfuric Acid

Alloy 20 is popular for its outstanding resistance to sulfuric acid at all concentrations, making it the best choice for chemical processing applications.

- Chloride Stress Corrosion Cracking Resistant

Our products are made to resist pitting and stress corrosion caused by chlorides and other destructive chemicals.

- Outstanding Mechanical Strength

It keeps high strength at both ambient and elevated temperatures, ensuring trustworthy operation in highly demanding environments.

- Flexible Valve Configurations

It is widely used in different designs like Ball, Gate, Globe, Check, and Butterfly valves, to meet the specific requirements of your system.

- Precision Engineering

It is made to conform to ASTM, ASME, and API standards, with severe tolerances for leak-proof performance.

Applications of Alloy 20 Valves

- Serve the chemical & Petrochemical Industries to handle acids, solvents, and harsh media.

- In Pharmaceutical Production, it is used for clean and sterile flow control.

- Food & Beverage Processing is used for corrosion-resistant flow systems for hygiene-sensitive procedures.

- Marine & Offshore Environments can be used in salty and corrosive atmospheres.

Why Choose Falcon Valves for Alloy 20 Valves?

Falcon Valves is a reliable name in high-performance valve solutions. Our Alloy 20 Valves are made with top-quality materials and advanced production techniques, confirming durability, security, and operational efficiency. Whether you’re seeking to control flow in a corrosive fluid pipeline or need custom-built valves for special applications, our professional team is ready to assist.

If you are interested in buying Alloy 20 Valves and have more questions, contact our team now. We are ready to serve your needs for the best products.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Alloy Steel Valves |

| Material | Alloy Steel |

| Pattern | Plain |

| Country of Origin | India |

| Finish | Polished |

| Usage | Industrial |

chrome moly/alloy steel valves f11/f22/f5/f9

falcon manufactures and stocks a large range of ‘chrome-moly’ valves. these valves are manufactured from low alloy steel containing chromium and molybdenum making them suitable for higher temperature service especially for higher pressure and temperature combinations. in addition, these valves have the added advantage of anti-corrosive properties. grades include forged astm a182 f5, f5a, f9, f11 and f22, and their cast equivalents astm a217 c5, c12, wc5, wc6 and wc9. higher grades like a112 f9/astm a217 c12a are available on an indent basis.

types

- alloy steel gate valves

- alloy steel globe valves

- alloy steel check valves

size

- gate valve: ¼” to 48”

- globe valve: ¼” to 24”

- check valve: ¼” to 36”

pressure rating

- 150# to 2500#

end connections

- flanged

- butt weld

- socket weld